History

-

Home > History

2023

2022

2021

2020

2019

2016

2013

2010

2008

2023

2022

2021

R&D IPC width control system

We R&D IPC width control system, no artificial measurement required. Through visual management, can monitor many width machine at the same time to ensure bag width and quality production.

2020

R&D weight loss liquid quantitative system

We R&D weight loss liquid quantitative system to solve the problem of sticky raw materials.

2019

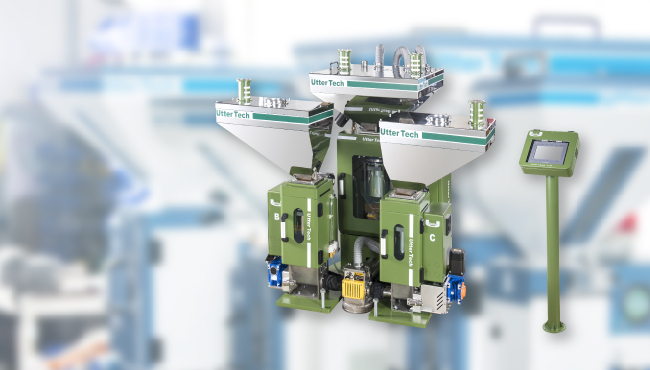

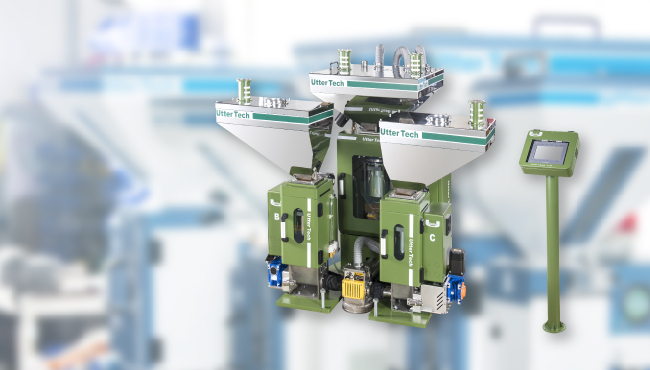

R&D weight loss master-batch quantitative system

In order to increase the accuracy of master-batch addition, we R&D weight loss master-batch quantitative system. It can solve the problem of large density difference between master-batch and main raw material. Also, the machine allowing quantitative feeding, well mixed color before and after, and stable quality.

2016

R&D weight loss powder quantitative control system

We R&D weight loss powder quantitative control system, solving the problem of powder bridging. Simultaneously, it can set proportion with shatter reclaimed material and powder material, stable feeding and production. Meanwhile, in respond to the trend of intelligent manufacturing, the remote connect system is also developed for customers to choose.

2013

Develop weight loss composite pelletize system

We develop weight loss composite pelletize system, which can calculate precise percentage and adjust proportion at any time between 2-6materials.

2010

R&D weight loss film thickness control system

We R&D weight loss film thickness control system, which can solve the problem of uneven thickness of plastic bags and large voltage difference between morning and night in the factory. We will give tutorials for customers as well.

2008